QUALITY POLICY

QUALITY POLICY

Since we began operations, MODEPSA has been serving mining and infrastructure projects alongside demanding, high-profile clients who require safe products of the highest possible quality for their works.

That is why we focus a large part of our resources and objectives on maintaining and improving our quality control, production process, staff training, and the procurement of the best possible raw materials every single day.

PRODUCTION PROCESS

There are two production lines:

Automatic (Cold)

- Raw material preparation

- Forming and/or pressing

- Thread rolling

According to the material and finish required by the client, the following processes are carried out:

- Pavonado

- Tratamiento térmico

- Zincado o Tropicalizado

- Galvanizado

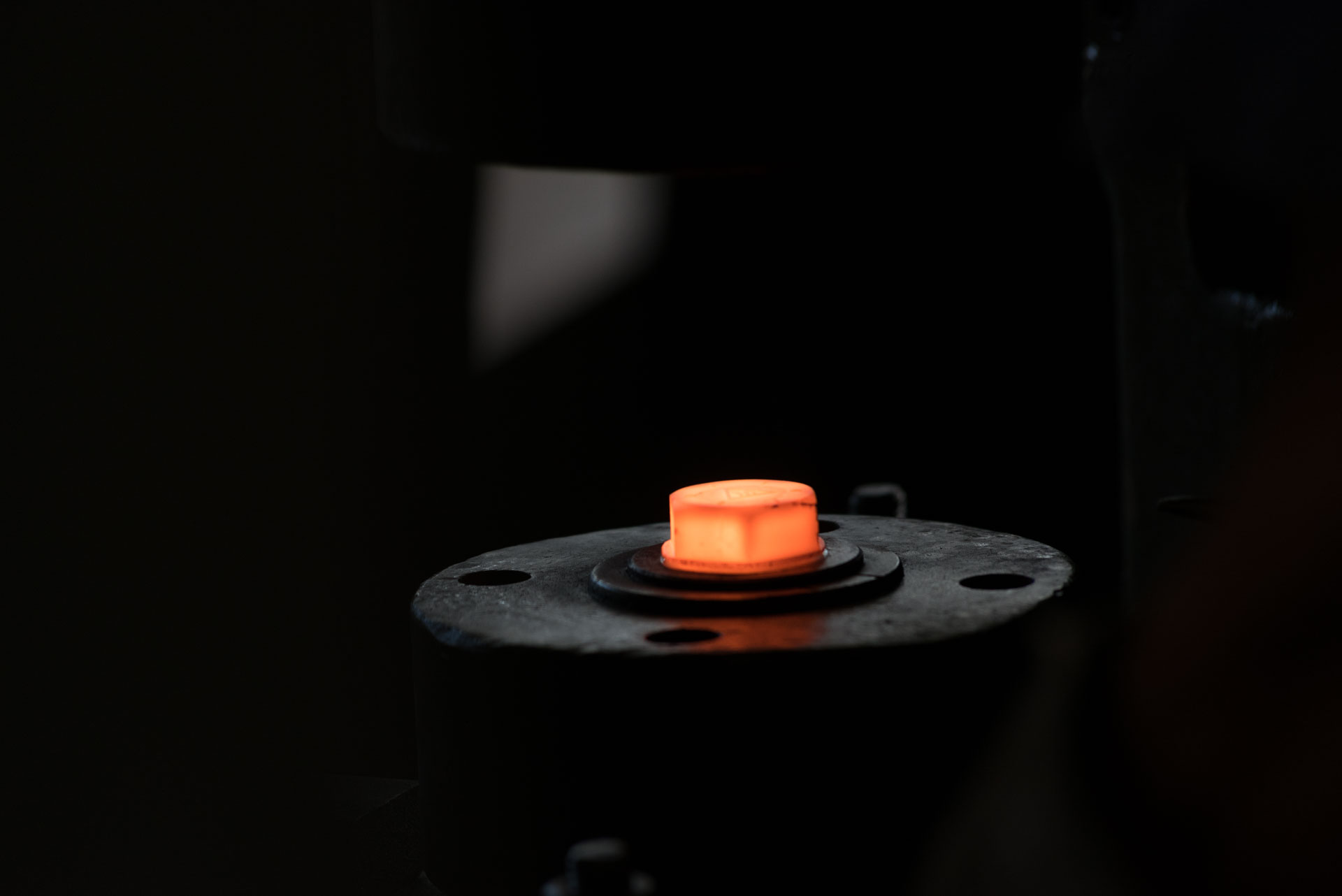

Forging (Hot)

- Cutting

- Forging

- Reducing and rolling

During the production process, the necessary quality controls are carried out to ensure compliance with standards.

QUALITY CONTROL

In recent years, Modepsa has focused on increasing the capacity and number of quality controls, due to the growing quality demands from our clients.

Quality control for the manufacturing of our products begins with our raw material suppliers, who are constantly approved and evaluated by our Quality Control and Logistics departments.

We also carry out quality controls on all our products by batch and by heat, ensuring full traceability of each product.

Our products comply with International Technical Standards such as ASTM, SAE, ASME, ANSI, AISI, ISO, and DIN.

This is done using equipment and tools properly calibrated by entities authorized by Inacal.

THE TESTS, ANALYSES, AND CONTROLS PERFORMED ON OUR PRODUCTS ARE THE FOLLOWING:

- Products with zinc coatings, whether hot-dip or cold by electroplating, are subjected to a thickness verification using a calibrated Thickness Gauge to ensure compliance with the corresponding standards ASTM F2329 or ASTM F1941, respectively.

- Metallographic Analysis of our final products is performed to determine the microstructural constituents obtained from the steel that has undergone heat treatment by quenching and tempering.

- Our products undergo a testing method to determine surface decarburization, based on the description in ASTM F2328.

- Structural bolts, and bolts in general, are subjected to Magnetic Particle Analysis quality control to detect and rule out the presence of possible cracks in the products.

- Additionally, if required by the client, our products are subjected to impact mechanical tests using the CHARPY method, which serves to determine the toughness of our products, especially for low-temperature applications, under ASTM E23.