Since we started operations, MODEPSA has been serving mining and infrastructure projects with demanding and high-standing clients, who require safe products of the best possible quality for their works.

This is why we focus a large part of our resources and objectives on maintaining and improving our quality control, production process, staff training and obtaining the best possible raw material every day.

There are two production lines:

Automatic (Cold)

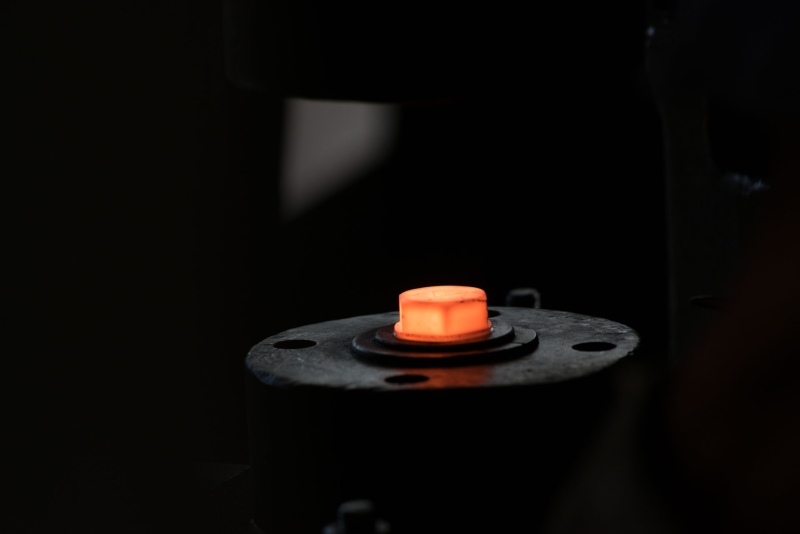

Forge (Hot)

Depending on the material and finish required by the customer, the following is done:

During the production process, the necessary quality controls are carried out to guarantee compliance with the standards.

In recent years, Modepsa has focused on increasing the capacity and quantity of quality controls, due to the increase in quality demands from our clients.

Quality control for the manufacture of our products begins with our raw material suppliers, who are constantly approved by our Quality Control and Logistics area.

We also carry out quality controls on all our products by batch and by casting, keeping a complete traceability of each product. Our products are governed by International Technical Standards such as ASTM, SAE, ASME, ANSI, AISI, ISO and DIN.

This is done using equipment and tools duly calibrated by entities authorized by Inacal.

Phone:

(01) 203 8000

Cell phone:

+51 998 325 201

+51 998 364 776

+51 981 134 379

Email:

Address:

Delta 185, Callao 07006